- Envirocrete Calgary AB

- Mar 31, 2019

- 4 min read

Updated: Nov 26, 2022

Pouring in concrete in extreme temperatures can be quite challenging for concrete contractors in this post we’ll talk about problems and solutions. Experts agree that the ideal temperature to pour concrete is around 12°, when pouring concrete below 5° and above 30°. We'll talk about some of the main problems that can occur, the best ways to tackle them making pouring and finishing easier, while providing an excellent product.

How does concrete cure?

Basically concrete cures by a process called hydration. Where water is added to the concrete mix to make a workable paste usually of cement, sand, and crushed rock. The cement reacts with the water forming crystals around the aggregate particles, as the cement hydrates and the excess water is evaporated through the top of the slab most of it in the first 24hrs.

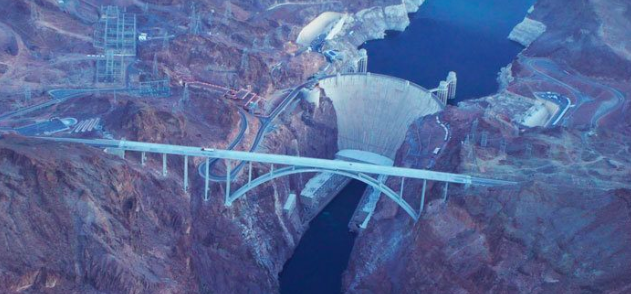

Then slowly over years and years this process continues and concretes strength increases more and more over that time. This reaction creates heat in the concrete in an exothermic reaction. It was said that the Hoover dam will take 125 years to fully cure from the time it was poured.

How long does concrete take to set?

In normal conditions concrete can take 2-20 hours to set depending on certain factors such as:

• Temperature outside the slab

• Wind speed

• Sun exposure

• Is the concrete an old hot load from the batch plant?

• Size of aggregate being used

• Cement ratio in concrete mix

• Whether coloured oxide added

Pouring in colder conditions below 5°

When pouring concrete in cold conditions there are a few issues that can arise. The 2 main issues will be preventing the concrete from freezing and the costs associated in doing so. Here are some of the problems:

• Water in the concrete freezing

• Loss of concrete strength due to being frozen and thawed out, can be up to 50%

• Increased costs in preventative measures to stop the concrete freezing

- Thawing the frozen ground out and removing all ice and snow if required

- Erecting timber framing and tarps for a sealed enclosure around the slab

- Gas heating pre and post pour for days

- Extra labour associated with setting up the horded enclosure

- Concrete batch plants charge more for heated aggregates and hot water in the concrete mix

- Use of chemical accelerators such as calcium chloride

- Use a plasticizers that replace water in the mix and help with the concrete not freezing

- Using fly ash with cement reacts better to colder conditions

Pouring in higher temperatures above 30°

Pouring concrete in extremely high temperatures can pose its own problems as well. Not only are the high temperatures an issue but also wind can greatly speed up the curing (hardening) process dry the top of the concrete out and lead to severe cracking a concreter’s worst nightmare.

Also high humidity will be problematic if there is allot of moisture in the air the existing water in the slab will not be able to evaporate properly and lead to excess water on top of the slab (bleed water), while its getting very hard underneath the bleed water must be removed before concrete finishing starts other wise premature delaminating, blistering, and cracking can occur.

Problems pouring concrete in high heat, high humidity, or high wind speeds

• Too much evaporation to fast will lead to large cracks

• Increased labour required to handle faster placing and finishing times

• A higher risk of cold joints between loads

• Lower compressive strength (Mpa) as more water is required to keep a workable slump

• Loss of strength and durability over time

• Greater shrinkage rates increasing the likelihood of cracking over time

Solutions to pouring concrete in hot temperatures and harsh conditions

• Increase manpower to handle the faster speeds and prevent the concrete from flashing

• Add ice to the concrete mix at the batch plant as well as water

• Add evaporation retarders at the batch plant to slow the concrete process

• Provide shade or wind shields over the concrete wherever possible

• Always soak down ground and spray forms with water before placing concrete

• Pour concrete in smaller sections to decrease concrete sun exposure

• Pour early in the morning or at night for cooler temperatures

• Put in more control joints at smaller intervals can help prevent cracking

Conclusion

Pouring concrete in adverse conditions can pose a few problems following the preventative steps up above can negate allot of these issues making pouring and finishing allot easier as well as providing a better product. Remember concrete waits for no one so it’s always good to be 1 step ahead and have all bases covered with good planning and prep work done beforehand.

If you would like to know more about concrete cracking and some more preventative measures

If you would like to get some concrete work done and where interested in a free online estimate emailed straight to you

Comments